A layisha iseliempeleni iyithuluzi eliguqula isignali enkulu ibe into ephumayo kagesi elinganisekayo. Uma usebenzisa i-alayisha iseli, indawo yokusebenza yangempela ye-layisha iseli kufanele kucatshangelwe kuqala, okubalulekile ekukhetheni ngendlela efanelelayisha iseli. Kuhlobene nokuthilayisha iseli ingasebenza ngokujwayelekile, impilo yayo yokuphepha nokuphila kwesevisi, ngisho nokwethembeka nokuphepha kwayo yonke insimbi yokukala.

Umthelela wemvelo endawenilayisha iseli ikakhulukazi kuhlanganisa izici ezilandelayo:

(1) Izinga lokushisa eliphakeme lidala izinkinga ezinjengokuncibilika kwezinto zokumboza, ukushisela okuvulekile kwamajoyinti e-solder, noshintsho lwesakhiwo ekucindezelekeni kwangaphakathi kwe-elastomer. Ngobalayisha iselis ukusebenza ezindaweni ezishisayo, izinga lokushisa eliphezululayisha iselis zivame ukusetshenziswa; ngaphezu kwalokho, izinto ezifana nokushisa ukushisa, ukupholisa amanzi noma ukupholisa umoya kufanele kwengezwe.

(2) Ithonya lothuli nomswakama kumjikelezo omfushane we-layisha iseli. Kulesi simo semvelo, alayisha iseli nge highumoya-ukuqina kufanele kukhethwe. Okuhlukilelayisha iselis banezindlela ezihlukene zokuvala, futhi zaboumoya-ukuqina yehluke kakhulu.

Izimpawu ezivamile zihlanganisa ukugcwaliswa kwe-sealant noma ukumboza; ama-rubber pads ahlanganiswe ngomshini futhi avaliwe; i-welding (i-argon arc welding, i-plasma beam welding) kanye ne-vacuum nitrogen yokugcwalisa izimpawu.

Ngokombono womphumela wokuvala, ukufaka uphawu nge-welding kungcono kakhulu, futhi ukugcwalisa nokufaka uphawu lokumboza yikona okumpofu kakhulu. Ngobalayisha iselis ezisebenza endaweni ehlanzekile neyomile yasendlini, ungakhetha i-glue-sealedlayisha iseli, futhi kwabanyelayisha iselis ezisebenza endaweni enomswakama futhi enothuli, kufanele ukhethe uphawu lokushisa lwe-diaphragm noma uphawu lwe-diaphragm welding, ukupompa I-vacuum nitrogen egcwelelayisha iseli.

(3) Endaweni egqwala kakhulu, njengomswakama kanye ne-asidi, ezolimaza i-elastomer noma ibangele ukujikeleza okufushane, indawo yangaphandle kufanele ifafazwe ngokweqile noma kufaneleembozwe ngeinsimbi engagqwali , enokumelana nokugqwala okuhle nokuhleumoya-mpilo.

(4) Umthelela wenkambu ye-electromagnetic onload iseli isignali yokuphazamiseka kokuphumayo. Kulokhu, ukuvikelwa kwe-load iseli kufanele ibhekwe ngokuqinile ukuze kubonakale ukuthi ayinawo yini amandla kazibuthe kagesi.

(5) Ezivuthayo neziqhumane azigcini nje ngokudala umonakalo ophelelelayisha iseli, kodwa futhi ibeka usongo olukhulu kwezinye izinto zokusebenza nokuphepha komuntu siqu. Ngakho-ke,layisha iseliUkusebenza ezindaweni ezivutha umlilo neziqhumayo kubeka phambili izidingo eziphakeme zokusebenza kokuvikela ukuqhuma: ukuvikela ukuqhumalayisha iselis kumele kukhethwe ezindaweni ezivuthayo neziqhumayo. Isembozo sokuvala salokhulayisha iseli akumele nje ucabangele yayoumoya-mpilo, kodwa futhi Amandla okuvimbela ukuqhuma, kanye nezindawo zokungangeni kwamanzi, umswakama-umswakama kanye nokuqhuma kwezintambo zezintambo kufanele zicatshangelwe.

Okwesibili, ukukhethwa kwenombolo nobubanzi belayisha iselis.

Ukukhethwa kwenombolo yelayisha iselis kunqunywa ngokuvumelana nenjongo yensimbi yokukala ye-elekthronikhi kanye nenani lamaphuzu umzimba wesikali okudingeka uwasekele (inani lamaphoyinti asekelayo kufanele linqunywe ngokuvumelana nomgomo wokwenza isikhungo sejiyomethri sokudonsela phansi komzimba wesikali siqondane nesikhungo sangempela samandla adonsela phansi). Ngokuvamile, ezininganalayisha iselis asetshenziselwa umzimba wesikali onamaphuzu amaningana asekelayo. Kodwa-ke, kweminye imizimba yesikali esikhethekile njengezikali ze-electronic hook, eyodwa kuphelalayisha iseli ingasetshenziswa. Kwabanyengogesi izilinganiso ezihlanganisiwe, ukukhethwa kwelayisha iseli kufanele kunqunywe ngokwesimo sangempela. inombolo.

Ukukhethwa kwe-layisha iseli ububanzi bunganqunywa ngokuya ngokuhlolwa okuphelele kwezici ezifana nenani eliphezulu lesisindo lesikali, inani elikhethiwe.layisha iselis, isisindo sakho somzimba wesikali, umthwalo ongase ube yi-eccentric kanye nomthwalo oguqukayo. Ngokuvamile, ukusondela kobubanzi be-layisha iseli kungomthwalo owabelwe ngamunyelayisha iseli, ukukala kwayo kuyoba nembe kakhudlwana. Nokho, ekusetshenzisweni kwangempela, kusukela umthwalo isetshenziswalayisha iseli kuhlanganisa isisindo somuntu siqu, isisindo se-tare, umthwalo we-eccentric kanye nomthelela wokudlidliza wesilinganiso ngaphezu kwento okufanele ikalwe, izici eziningi okufanele zicatshangelwe lapho kukhethwalayisha iseli ibanga ukuqinisekisa lokholayisha iseli ukuphepha nokuphila isikhathi eside.

Ifomula yokubala ye-layisha iseli ububanzi bunqunywa ngenani elikhulu lokuhlola ngemva kokucabangela ngokugcwele izici ezihlukahlukene ezithinta umzimba wesikali.

Ifomula imi kanje:

C=K-0K-1K-2K-3(Wmax+W)/N

C-ububanzi obulinganiselwe bokukodwalayisha iseli; W-isisindo somzimba womuntu siqu; Wmax-inani eliphezulu lesisindo sengqikithi yento ekalwayo; N-inani lamaphoyinti okusekela asetshenziswa umzimba wesikali; K-0-isici somshuwalense, ngokuvamile phakathi kuka-1.2 no-1.3; K-1-i-coefficient yomthelela; K-2-isikhungo se-gravity offset coefficient of the scale body; K-3-I-coefficient yomfutho womoya.

Isibonelo: isikali samaloli kagesi esingu-30t, isisindo esiphezulu singu-30t, isisindo somzimba esikalini singu-1.9t, kusetshenziswa ezinelayisha iselis, ngokuya ngesimo sangempela ngaleso sikhathi, khetha isici somshuwalense K-0=1.25, isici esinomthelela K-1=1.18, Isikhungo se-gravity offset coefficient K-2-=1.03, i-coefficient yokucindezela komoya K-3=1.02, zama ukunquma ithonilayisha iseli.

Isixazululo: Bala ifomula ngokwe-layisha iseli ububanzi:

C=K-0K-1K-2K-3(Wmax+W)/N

Kuyaziwa ukuthi:

C=1.25×1.18×1.03×1.02×(30+1.9)/4

=12.36t

Ngakho-ke, alayisha iseli ngebanga le-15t lingakhethwa (i-tonnage ye-layisha iseli ngokuvamile i-10T, 15T, 20t, 25t, 30t, 40t, 50t, njll., ngaphandle uma i-odwe ngokukhethekile).

Ngokusho kokuhlangenwe nakho, i-layisha iseli ngokuvamile kufanele isebenze phakathi kuka-30% kuya ku-70% wobubanzi bayo, kodwa kwamanye amathuluzi okukala anamandla amakhulu ngesikhathi sokusetshenziswa, njengezikali zesitimela esishintshashintshayo, izikali zamaloli eziguqukayo, izikali zensimbi, njll., lapho kukhethwa.layisha iselis, Ngokuvamile, kuyadingeka ukwandisa ububanzi bayo, ukuzelayisha iseli isebenza ngaphakathi kuka-20% kuya ku-30% wobubanzi bayo, ukuze inqolobane yokukala yelayisha iseli iyanda ukuze kuqinisekiswe ukuphepha nempilo yelayisha iseli.

Futhi, cabangela ukusebenza kohlobo ngalunye lwelayisha iseli.

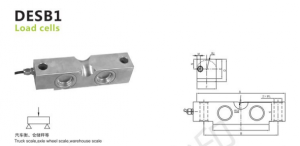

Ukukhethwa kwe-layisha iseli uhlobo ikakhulukazi luncike ohlotsheni lwesisindo kanye nesikhala sokufaka ukuqinisekisa ukufakwa okufanele kanye nesisindo esiphephile nesithembekile; ngakolunye uhlangothi, izincomo zomenzi kufanele zicatshangelwe. Abakhiqizi ngokuvamile bacacisa ububanzi bokusetshenziswa kwe-layisha iseli ngokwamandla elayisha iseli, izinkomba zokusebenza, ifomu lokufaka, uhlobo lwesakhiwo, nokokusebenza kwe-elastomer. Isibonelo, i-aluminium cantilever beamlayisha iseliama-s afanele izikali zentengo, izikali zeplathifomu, izikali zamacala, njll.; insimbi Cantilever ugongololayisha iseliama-s afanele izikali ze-hopper, izikali zebhande le-electronic, izikali zokuhlunga, njll; ibhuloho lensimbilayisha iseliama-s afanele izikali zikaloliwe, izikali zamaloli, izikali ze-crane, njll.; ikholomulayisha iseliama-s afanele izikali zamaloli, izikali zikaloliwe eziguqukayo, nezikali ze-hopper ezinamathani amakhulu. Linda.

Ekugcineni, kukhona ukukhethalayisha iseli ikilasi lokunemba.

Izinga lokunemba kwe-layisha iseli ihlanganisa izinkomba zobuchwepheshe njengelayisha iseliukungeyona i-linearity, ukukhasa, ukululama kokukhasa, i-hysteresis, ukuphindaphinda, kanye nokuzwela. Lapho ukhethalayisha iselis, ungamane uphishekele izinga eliphezululayisha iselis, kodwa cabanga ukuhlangabezana nezimfuneko zokunemba zezikali zikagesi kanye nezindleko zazo.

Ukukhethwa kwe-layisha iseli ikilasi kumele lenelise lezi zimo ezimbili ezilandelayo:

1. Hlangana nezidingo zokufakwayo kwensimbi. Ithuluzi lokubonisa isisindo libonisa umphumela wokukala ngemva kokucubungula isignali yokuphumayo yelayisha iseli ngokusebenzisa i-amplification kanye nokuguqulwa kwe-A/D. Ngakho-ke, isignali yokuphuma kwe-layisha iseli kumele kube kukhulu noma kulingane nosayizi wesiginali yokufaka edingwa imitha, okungukuthi, ukuzwela kokuphumayo kwe-layisha iseli ithathelwa indawo yifomula efanayo ye-layisha iseli kanye nemitha, futhi umphumela wokubala kufanele ube mkhulu noma ulingane nokuzwela okokufaka okudingekayo imitha.

Ifomula efanayo ye-layisha iseli kanye imitha:

Load cell ukuzwela kokuphumayo * i-excitation power supply voltage * ubuningi besisindo sesikali

Inani lokuhlukaniswa kwesilinganiso * inombolo yelayisha iselis * ububanzi belayisha iseli

Isibonelo: isikali sokupakisha esinesisindo esingama-25kg, inani eliphezulu lokuhlukaniswa yi-1000. Tumzimba wesikali usebenzisa uhlobo lwe-3 L-BE-25layisha iselis, ububanzi bungama-25kg, ukuzwela kungu-2.0±0.008mV/V, i-arch bridge voltage pressure 12V. TIsikali usebenzisa imitha AD4325. Buza ukuthi ngabe ilayisha iseli esetshenzisiwe ingafanisa imitha.

Isixazululo: Ngemva kokubonisana, ukuzwela okokufaka kwemitha ye-AD4325 ngu-0.6μV/d, ngakho ngokusho kwefomula ehambisanayo yelayisha iseli kanye nemitha, isignali yangempela yokufaka yemitha ingatholakala njenge:

2×12×25/1000×3×25=8μV/d>0.6μv/d

Ngakho-ke, i-layisha iseli esetshenzisiwe ihlangabezana nezidingo zokuzwela okokufaka kwensimbi futhi ingafanisa ithuluzi elikhethiwe.

2. Hlangana nezidingo zokunemba zaso sonke isikali sikagesi. Isikali sikagesi sakhiwe ikakhulukazi izingxenye ezintathu: umzimba wesikali,layisha iseli kanye nensimbi. Lapho ukhetha ukunemba kwe-layisha iseli, ukunemba kwelayisha iseli kufanele ibe phezulu kancane kunenani lokubala letiyori, ngoba ithiyori ivamise ukukhawulelwa izimo eziqondile, njengezikali. Amandla omzimba mabi kakhulu, ukusebenza kwensimbi akukuhle kakhulu, indawo yokusebenza yesilinganiso imbi kakhulu nezinye izici ngqo.kuthinte i izimfuneko zokunembaesikalini.

Isikhathi sokuthumela: Aug-11-2022